Penny Whistle

The Tinwhistle, Pennywhistle, Irish Whistle, Whistle, Fipple Flute, Vertical Flute, Tin Flute, Flageolet, Cuisle, Culseach, Feadan, Feadog Stain are all interchangeable terms.

They all refer to a simple 6 hole end blown flute popular in many lands, perhaps most famously in Ireland, England, and Scotland.

No matter what you call it, it is a simple six-hole instrument played by blowing through the fipple (mouthpiece) attached to one end.

Pea Whistle

Pea Whistle

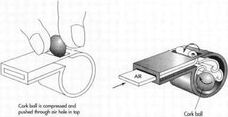

Despite common terminology, the ball contained in pea whistles is actually made of cork (except for inexpensive, plastic versions). American Whistle Corporation has developed a synthetic cork material that behaves like natural cork in every respect except that it does not absorb any moisture. This helps keep the ball from getting stuck inside the whistle and not swirling freely.

How a Pea Whistle is Made

The following process is used to manufacture the type of metal pea whistle that is commonly associated with American military, police, and sports applications.

1. Sheets of brass are unrolled from supply reels and fed into stamping machines. Blanks are die-cut for the whistle's three primary pieces: the rectangular air-input tube, the barrel-shaped chamber, and a fitting for the back of the whistle that will hold a ring to which the user can attach a lanyard (cord). Different grades (hardnesses) of brass are used for the two main functional pieces of the whistle.

2. The pieces pass through a series of stamping dies and presses that perform a progression of cutting and bending operations to form them into the required shapes. The company name (or a customer's custom logo) is stamped onto what will become the top of the whistle.

3. Custom-designed machines hold the three parts of the whistle in position while solder is applied to the joints and the assembly is heated, sealing the parts together.

4. Each whistle is mounted in another machine, where a vibratory sander smooths the exterior surface to a pre-plate finish.

5. A nickel or chrome plating is applied to the exterior of the whistle.

6. The cork ball is inserted in the whistle. A machine compresses the cork and shoots it through the slot on top of the whistle. Once inside, the cork returns to its original shape, making it too large to fall out through the slot.

7. A metal lanyard ring is inserted into the holder on the back of the whistle.

8. Standard whistles are packaged in a plastic bubble attached to a cardboard backing. More expensive versions, suitable for use as gifts or awards, are mounted in a plastic box or a wooden case.

Boatswain's Pipe

The use of the Boatswain's pipe is almost lost in antiquity, but we know that the ancient galley slaves of Greece and Rome kept stroke by the flute or whistle.

The Pipe or Call was originally used as a badge of rank also and as such was worn by the Lord High Admiral of the Royal Navy and was known as the Whistle of Honor. It was made of gold and suspended from the neck by a gold chain.

These officers also carried a Whistle of Command, which was of silver, and was used for passing orders and blown as a salute to certain personages. It was enjoined that it should be blown on these occasions "three several times."

The first time it can be found being used to actually to pass an order was during the Crusade of 1248, when the Cross-bowmen were piped to come on deck and engage the enemy.

The present form of the bosun's pipe is actually a facsimile of that taken from the body of the infamous pirate Andrew Barton by Admiral Lord Howard.

At times the whistle seems to have been a somewhat weighty instrument. It is believed that it was Henry VIII who laid down the names of the parts of the whistle, and the weight of the Whistle of Honor was put at 12 "Oons" or ounces of gold, while the chain was to be of a certain value of golden ducats."

Listen to some of the calls: